Shop No. A1/B, Ground Floor, Mahavir Darshan Building, 26,

Khambatta Lane, Opp. 8th Khetwadi Back Road, Mumbai 400004 India- +91-8802222222

mitesh@miprasteel.com

sales@miprasteel.com

Copper nickel alloys, also known as Cu-Ni, offers excellent corrosion resistance, especially in marine salt water environments. Copper nickel alloys that are generally chosen for sea water parts and service equipment contains 10 to 30 percent nickel.

Mipra Steel stocks C70600 and C71500 Copper Nickel pipes, which are commonly used in seawater piping due to its complete resistance to barnacles. Due to Its resistance of various sea organisms, this alloy makes seawater desalination, water systems, fire fighting systems, and similar applications very reliable.

These various alloys also have important additions of iron and manganese, which are necessary to maintain good corrosion resistance in the harsh environments. Aside from being very corrosion resistant to sea water, copper nickel alloys are very thermally stable. Copper nickel is most commonly used in applications such as electrical and electronic products, tubes for condensers in ships and power plants, various marine products, including valves, pumps, fittings, and sheathing for ship hulls.

Applications

Grade:

90/10, 70/30Shapes:

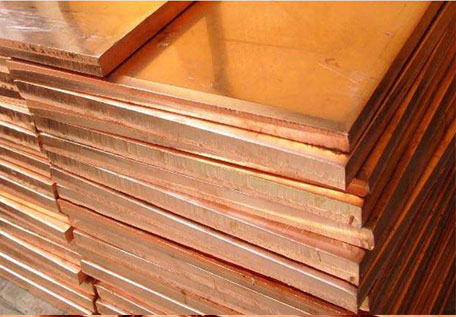

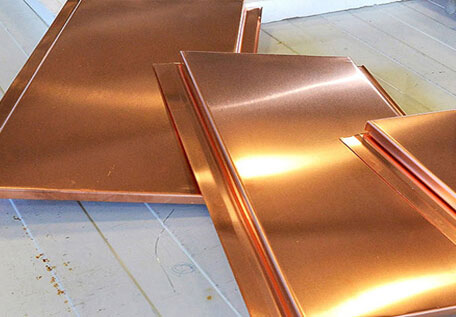

Sheet : Plate, Coil, Shim, Foil, Square sheet, rectangulare sheet, Square plate, rectangulare plate, Circle, Plate Cut, Sheet Cut, Flat, Patta, Ring, chquered plate, chquered sheet, Slit Coil.

round bar : square bar, hex bar, Bush, Wire.

Pipe: Round Pipe, Square Pipe, Hollow Pipe, Rectuangular Pipe, Bush, box pipe, Tube.

Pipes Fittings: Fastners.

Angle : Chanel, Beam, Flat.